Bending and Warping Defects

Defects

Casting distortion, including bending, warping, and out-of-flatness.

Cause

A combination of design flaws and operational inconsistencies.

Corrections

- Design corrections:

- Reduce tolerance allowance for tool construction: Allocate more tolerance to accommodate process variations rather than tool manufacturing variations.

- Refine shrinkage estimates: Avoid using a single shrinkage value for all dimensions; instead, use more accurate values for each dimension.

- Accurately assess process capabilities: Realistically evaluate the limitations of the casting process to ensure consistent results.

- Operational corrections:

- Maintain consistent ejection temperature: Ensure that both the casting and the die are at the same temperature before each ejection.

- Control hold time using a thermocouple: Replace timers with thermocouples for more precise hold time control.

- Enforce process consistency: Standardize variables such as die spray, cycle time, and cooling water flow rates to maintain consistent temperatures.

- Address uneven ejection forces:

- Evaluate ejector system design and ejector guide mechanism: Check for wear or design flaws that could cause uneven forces.

- Ensure uniform bumper pin lengths: Replace or adjust bumper pins to maintain consistent lengths.

- Verify ejector pin placement: Correct any misplacement of ejector pins that could create uneven forces.

- Eliminate drags: Address drags caused by worn or heat-checked dies, undercuts in the die, or stress on the casting during die opening.

- Check machine linkage: Inspect machine linkage for wear that could affect ejection forces.

- Inspect tie bar bushings, platen shoes, and guide pins: Replace or repair worn components to maintain consistent operation.

- Increase draft allowance: Provide adequate draft, especially for short walls and internal cores, to facilitate easier ejection.

- Optimize ejection timing: Avoid premature ejection that could lead to distortion.

- Modify die dimensions if necessary: If all other factors are controlled and the casting shape remains unstable, adjust die dimensions to achieve desired specifications.

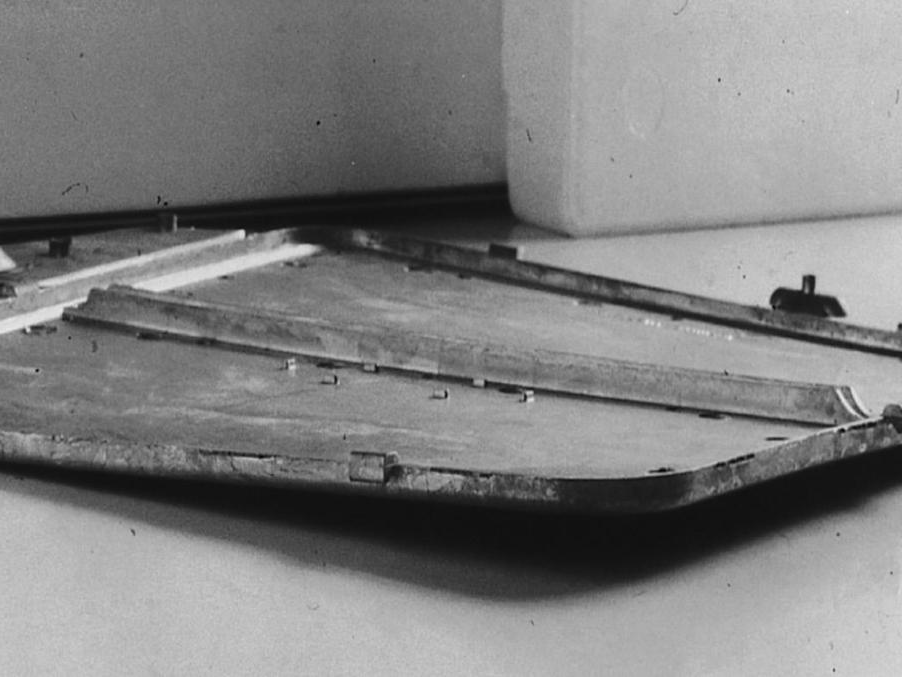

Bending. Thin casting bent at ejection.

Please note that the information provided in this article is intended to be a general guide to the causes and corrections of bending and warping in metal castings. However, it is important to note that the specific cause and correction of any particular defect will vary depending on the specific casting process, alloy, and other factors. Therefore, it is important to consult with an experienced and professional engineer to ensure that the correct diagnosis is made and the most suitable correction is chosen.