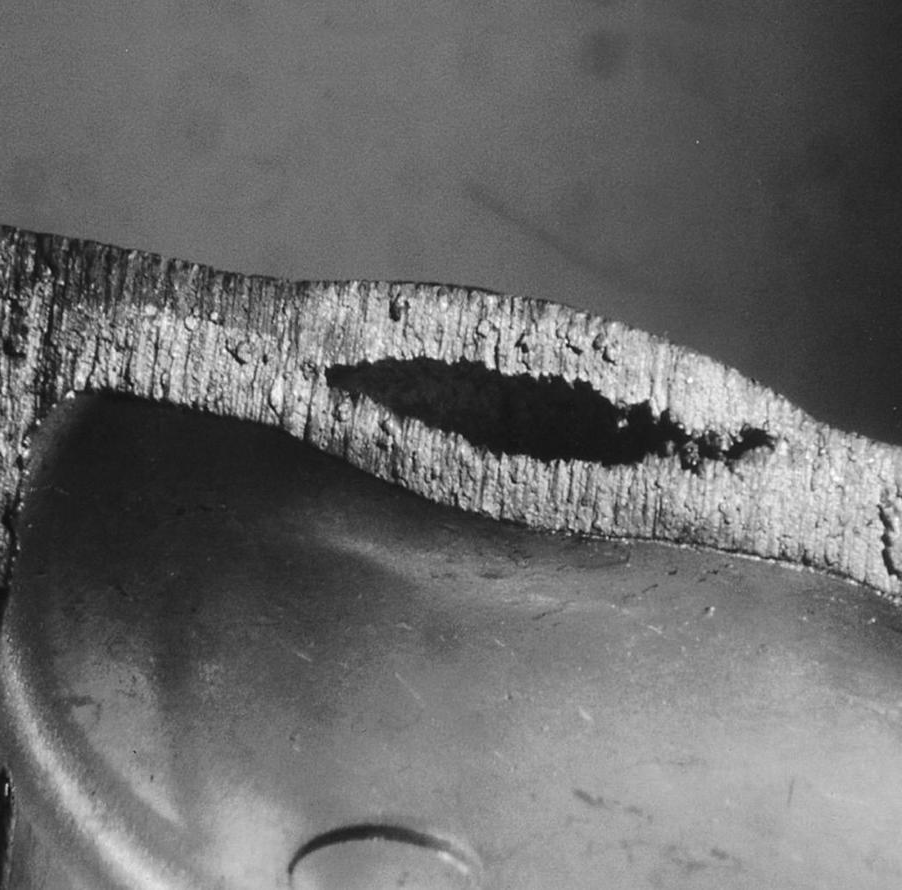

Blisters Defect

Defects

Bubbles of gas trapped just under the surface of the metal during die fill.

Cause

Gas trapped just under the surface of the metal during die fill.

Corrections

- Reduce gas porosity:

- Reduce trapped air.

- Reduce spray and plunger lubricant.

- Eliminate water on the die.

- Correct venting and vacuum problems.

- Cool the die:

- Cool the blister area with die spray.

- Cool the blister area by adjusting water lines.

- Cool the whole die by slowing the cycle time.

- Add fountains or baffles to the blister area.

- Cool the casting:

- Quench the casting in water immediately after ejection.

- Reduce metal temperature:

- Keep the process consistent.

- Correct gating or venting problems, or add vacuum.

Typical blister

Typical blister

Please note that the information provided in this article is intended to be a general guide to the causes and corrections of blisters in metal castings. However, it is important to note that the specific cause and correction of any particular defect will vary depending on the specific casting process, alloy, and other factors. Therefore, it is important to consult with an experienced and professional engineer to ensure that the correct diagnosis is made and the most suitable correction is chosen.