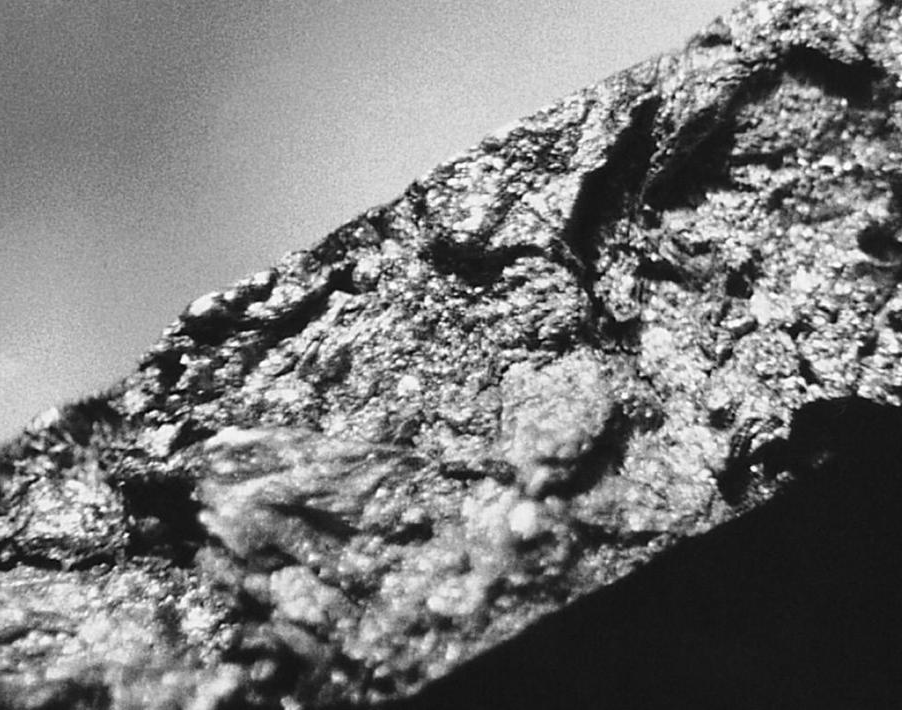

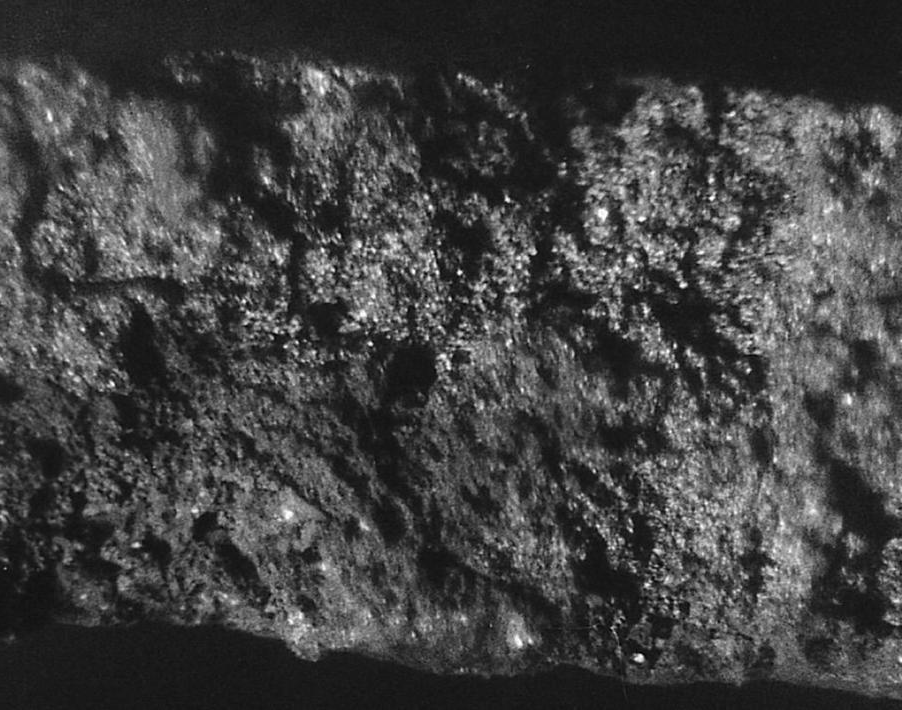

Leakers Defect

Defects

Cause

A loose dendritic structure inside the casting is exposed by an opening in the casting skin. This opening provides a leak path. Leakers are another version of shrinkage porosity.

Corrections

- Look for sharp corners at the spot where the leak occurs and add as much radius as possible.

- Cool the spot where the leak occurs with spray. Keep cooling even if the spray makes no visible difference.

- Thin the biscuit or reduce the variation in biscuit size. This can be a major cause of leakers in many shops.

- Try to keep the skin intact in the leaker area. To do this:

- Stop drags from solder or other sources.

- Reduce machining if possible. Keep the skin intact whenever possible.

- Try to keep the skin intact in the leaker area.

- Check for problems in the plunger, such as sticking and dragging.

- Check for poor pressure control. Verify the static and intensified pressure. Check intensifier performance.

- Add squeeze pins in the area of the leakers.

- Move the gate closer so that more pressure can be applied during solidification by the intensifier.

- Change the temperature balance. Cool the area where the leakers occur and heat the areas surrounding the leaker location.

- Keep the metal temperature consistent and run at a minimum.

- Check the constituents in the metal and do not allow variation.

- Keep the silicon content on the low side.

Please note that the information provided in this article is intended to be a general guide to the causes and corrections of leakers defects in metal castings. However, it is important to note that the specific cause and correction of any particular defect will vary depending on the specific casting process, alloy, and other factors. Therefore, it is important to consult with an experienced and professional engineer to ensure that the correct diagnosis is made and the most suitable correction is chosen.