Types of Chips: Understanding Their Meaning for Optimal Machining

Metal, under the skilled hand of a machinist and the bite of a cutting tool, reveals its story in the form of chips. These telltale slivers whisper valuable insights about the machining process, each shaped by a unique interplay of factors:

Material Compatibility: Think perfect harmony between tool and workpiece. Compatible properties lead to smooth, continuous ribbon chips. Imagine soft aluminum meeting a sharp, well-lubricated tool – a flawless waltz for effortless chip formation.

Cutting Operation: Different operations leave distinct signatures. Turning creates flowing ribbon chips, while drilling's percussive nature produces fragmented element chips. Milling, with its dynamic forces, might form twisted snarled chips if conditions aren't ideal.

Cutting Conditions: Speed, feed rate, and material removal rate orchestrate the dance. High speeds and low feed rates favor graceful ribbon chips, while slower speeds and higher feed rates can lead to disc-shaped washer-type chips or snarled chips due to increased pressure and heat.

Tool Geometry: The tool's design influences chip formation like a choreographer shapes movement. A sharp tool with a high rake angle facilitates smooth ribbon chips, while a blunt tool with a low rake angle might generate washer-type chips or fragmented element chips.

Lubrication: This critical factor reduces friction and heat, impacting the chip's form. Proper lubrication encourages smooth ribbon chips, while insufficient lubrication can lead to snarled chips or even tool breakage.

Decoding the Chip Symphony:

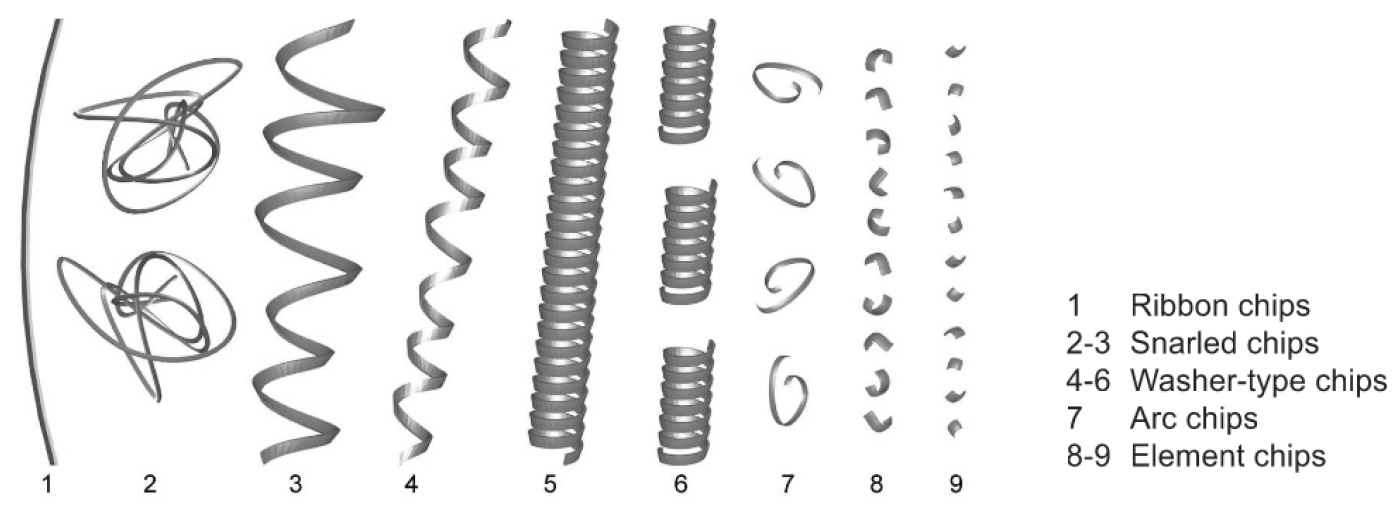

Ribbon Chips: Smooth, continuous, resembling rolled metal ribbons – signifying ideal cutting conditions and excellent surface finish.

Snarled Chips: Like twisted ribbons – revealing potential tool wear or the need for adjusted cutting conditions.

Washer-Type Chips: Disc-shaped fragments – hinting at tool issues or material properties needing different tool geometry.

Arc Chips: Crescent-shaped pieces – often indicating material hardness exceeding tool capabilities.

Element Chips: Tiny, irregular fragments – characteristic of brittle materials, suggesting low tool sharpness or high cutting forces.

By understanding these factors and the stories each chip type tells, machinists can become fluent in the language of their craft. This fluency unlocks a treasure trove of information, allowing them to fine-tune processes, optimize performance, and ensure quality – ultimately elevating their craft to an art form.