Understanding Molds and Dies: Differences, Types, and Applications

In the world of manufacturing, molds and dies are two instrumental tools that shape and form raw materials into finished or semi-finished products. Despite their shared purpose, these two distinct tools have their unique attributes, applications, and types.

Understanding Molds:

Molds are typically used in processes such as injection molding, blow molding, and casting. They are hollow containers filled with a liquid or pliable material, like plastic, glass, or metal. As the material solidifies or sets, it adopts the shape of the mold.

Types of Molds

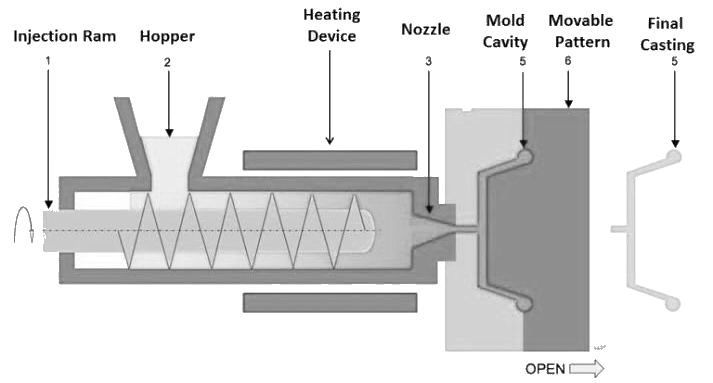

- Injection Molds: These molds are used in injection molding machines to produce parts by injecting molten material into the mold. They are commonly used for creating high-precision plastic parts in large quantities.

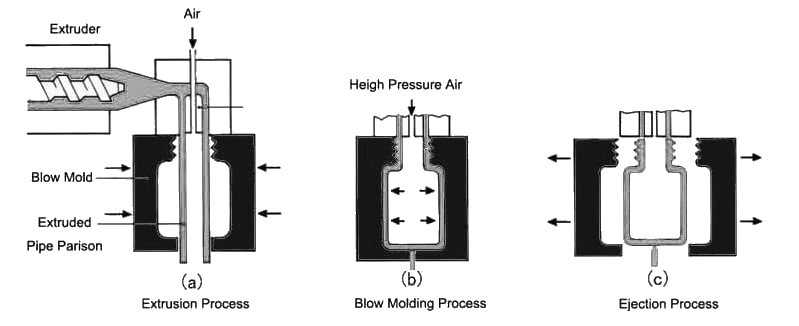

- Blow Molds: Blow molding is a manufacturing process used to produce hollow, thin-walled parts such as bottles and containers. In this process, a preformed plastic tube (parison) is placed into a mold cavity, and air pressure is applied, causing the tube to expand and conform to the shape of the mold.

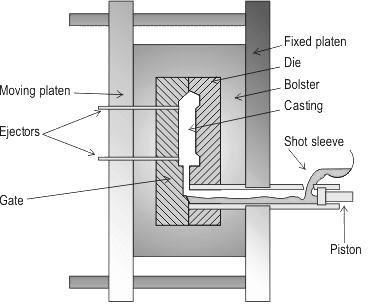

- Casting Molds: These molds are used in the casting process where molten metal or other materials are poured into the mold to create a part. Sand molds, ceramic molds, and metal molds are common types used in various casting processes like sand casting, die casting, and investment casting.

Understanding Dies

Dies, on the other hand, are used in processes like stamping and extrusion. They apply force to a material to cut, shape, or form it, often under high pressure. Dies are typically used with sheet metal and are an essential tool in metalworking industries.

Types of Dies

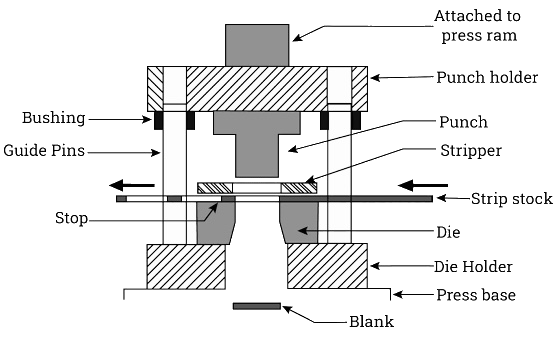

- Stamping Dies: These are used in a stamping operation where a sheet of metal is cut or shaped using a die that is mounted on a press. Examples of stamping dies include blanking dies, which cut out pieces of metal, and forming dies, which shape metal into a specific form.

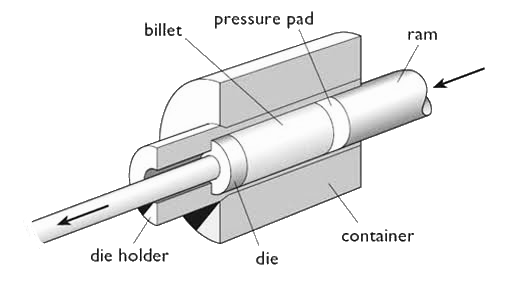

- Extrusion Dies: Extrusion is a process in which a material is pushed or drawn through a die of the desired cross-section. The two main types of extrusion are direct (forward) and indirect, which refer to the direction of the billet flow.

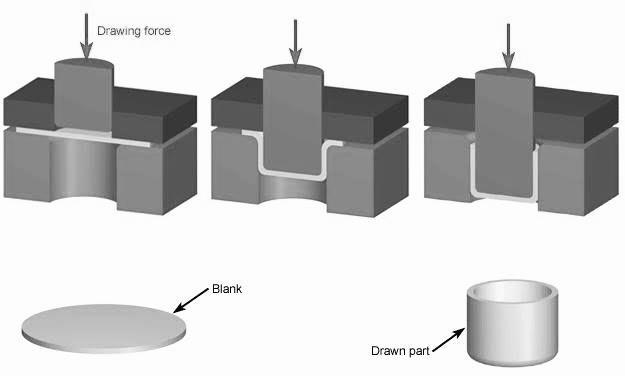

- Drawing Dies: These dies are used to reduce the cross-section of a wire or rod by pulling the material through a die opening. They are used in the production of wires, rods, and tubes.

Conclusion

Molds and dies are vital in manufacturing, each with their unique characteristics and applications. Understanding their differences and types can help in selecting the appropriate tool for a specific manufacturing process. Whether it's creating a plastic bottle or shaping a metal sheet, these tools play a crucial role in turning raw materials into finished products.